1, First clean up and then welding: if the lead of the parts to be welded has oil stains or rust, it is not easy to eat tin.The welder is equipped with a large transparent window to observe the entire welding process, which plays a very important role in product development and process curve optimization.Temperature control adopts high-precision intuitive intelligent controller, programmable perfect curve control, accurate temperature control, simple parameter setting and easy operation.It can complete all packaging forms of single - and double-sided PCB, such as CHIP, SOP, PLCC, QFP and BGA.A soldering machine, a screen printing table and two workers can complete nearly 100 maximal size PCB boards in a day, as well as thousands of small PCB boards.The soldering machine changes the way of cooling only by natural cooling or pulling the PCB out of the soldering machine, so that the reflow soldering process curve is more perfect, and the damage of surface mount devices and welding displacement problems are avoided.Even if the tin is firmly attached, it may lead to incorrect soldering.Therefore, be sure to scrape away the unnecessary stuff before applying the flux.Dip the pin in the rosin, then wipe the pin with a soldering iron containing tin until the pin can be lightly coated with solder.Currently, most electronic components are very solderable, so manual soldering does not require drip treatment, and components are not properly stored.If the component pins become oxidized or dirty, they need to be dripped.

2. Try to keep the solder stable without shaking: the welding material should be firmly clamped, especially in the welding stage.If missoldering is prone to occur during the curing phase, the solder joint will resemble bean curd residue.To stabilize the wrist while sitting and standing, you can also use a support pillow.

3, The amount of tin: the tin solder is immersed in enough amount to have sufficient size for welding.The scroll bars are bright and allow for smoother solder joints.If it's not tin, you can add it, but you have to wait for the previous solder to become the back solder, then remove the solder tip, and then someone will weld it, like a bird's nest stack with base flux.The result was a lot of solder, but weak tin solder.

4, master the temperature control skills: if the temperature is insufficient, the welding wire is poor in mobility, easy to cure, the temperature is too high and lead to drop welding, solder spot can not be suspended solder.

For proper temperature control, use the soldering iron corresponding to the power according to the size of the object.

Control the heating time, the non-standard automatic soldering machine uses the soldering head to pressurize the solder, and then heat to the solder.The heating time is described when the iron head automatically disseminates the object from the solder.In this case, the needle pierces the end opening and leaves a smooth, shiny solder spot without moving the solder tip away.And then the heating time is short.The temperature is not enough.Welding or smudging.The welded joints should be removed from the ship before the downstream heating time becomes too long.

5. Why do non-standard automatic soldering machines use less solder paste in welding?The solder paste is an acid assistant solder paste, which should be wiped clean or severely corrode the circuit.Therefore, solder paste should be avoided or used less.Rosin is a better solder when a rosin-free electrode is used.Dip the soldering iron into the tin, apply rosin, and weld quickly.

Rotary multi - station automati

Rotary multi - station automati ULiTOBOTS four axis double slid

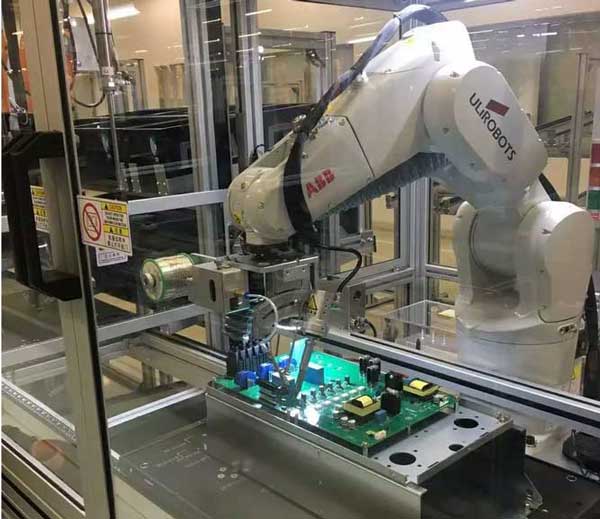

ULiTOBOTS four axis double slid Six axis manipulator line autom

Six axis manipulator line autom Single position precision const

Single position precision const